The key for these personal care product manufacturers, particularly those producing shampoo, is this — production efficiency does not equate to speed, but rather precision, flexibility, and reduction of waste. Introduction Of A Shampoo Filling Machine In Your Production Line Can Revolutionize Everything The following infographic provides a step by step summary on how to fully utilize the power of this technology to improve your productions.

Boost Your Production Speed

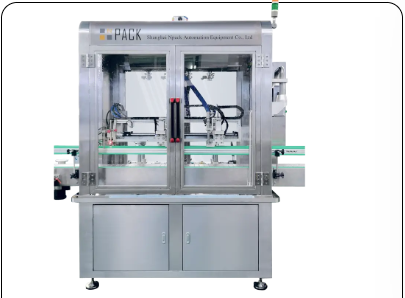

The filling unit of the shampoo is filled by means of the shampoo filling machine so that it can increase in production by the number of units per hour. Normal machines can fill 30 to 120 bottles per minute (based on the model) But make sure you production line can follow that kind of speed. A This could involve syncing upstream processes like mixing and downstream processes like capping and labeling to avoid bottlenecks.

Ensure Precise Fill Volumes

Not only do we require a certain level of accuracy so we can be sure the product is of quality, but also for cost-effective reasons. Today, fillers are more precise, often utilising volumetric or gravimetric filling systems to make sure the bottles being filled get the same exact product level. It is essential to keep this level of accuracy for this regular calibration and maintenance of the the filling machine. Enforce a regular maintenance schedule to maintain the machine in the optimum condition

Rapidly Adjust to Various Pack Sizes

Quick changeover between bottles, including different sizes and shapes could reduce downtime dramatically and improve reaction on the market. The majority of shampoo filling machines have the capability to easily adjust in order to handle a wide range of bottle types. Proper training of your staff will allow for implementing these changes quickly and safely, and extend the versatility of your machine, leading to an overall quicker response to market trends and consumer requirements.

Minimize Product Waste

Money can be wasted on products during filling. Shampoo filling machines are developed to reduce this waste, but proper adjustment and operation are necessary. Use Machine Data to Monitor and Adjust Fill Speeds and Volumes. This information can be used to recognize trends, like consistent overfills or underfills, so you can adjust the settings to minimize waste on Overfill Prevention Valves (OPVs).

Enhance Safety and Hygiene

As the care of the body is in question we must take the best of service and hygiene into account. The enclosed operation of a shampoo filling machine reduces human contact to the product, minimizing the exposure to contamination, to add to the overall safety in operation. Follow the manufacturer guidelines on the machine that you are using to do the sterilization work, it should be kept in a clean and sterilized condition regularly spep to keep those standards.

Train Your Team

A similar concept applies here as well, having the correct equipment and the proper skill-set is what operational efficiency is! It is essential that your staff is taught comprehensively in the operation, troubleshoot and maintenance of the shampoo filling machine. An established team can make the most of your machines, handle small issues without any interruptions and guarantee that stream your production process undergoes gradual enhancements.

By using this shampoo filling machine, you will be able to get the most benefits from these strategies. You can enhance your efficiency, product quality, and production flexibility in your company, which drives operational and market competenceiciencies and market competencies.